MAY 2024 PLUS: Traceability | Automation | Ingredients

1300 211 954 Motion.com.au Agriculture | Food and Beverage | Mining | Manufacturing | Quarry and Cement | Waste Water

CEO: John Murphy

COO: Christine Clancy

Managing Editor: Syed Shah

Editor: Adam McCleery

Ph: (02) 9439 7227

adam.mccleery@primecreative.com.au

Art Director: Michelle Weston

michelle.weston@primecreative.com.au

Sales/Advertising: Franck Casili

Ph: 0434 785 611

franck.casili@primecreative.com.au

Production Coordinator:

Salma Kennedy

Ph: (03) 9690 8766

salma.kennedy@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109 119

2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Copyright Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Cover Image: Motion Australia

Head Office

379 Docklands Drive

Docklands VIC 3008

Ph: +61 3 9690 8766

enquiries@primecreative.com.au

http://www.primecreative.com.au

Sydney Office

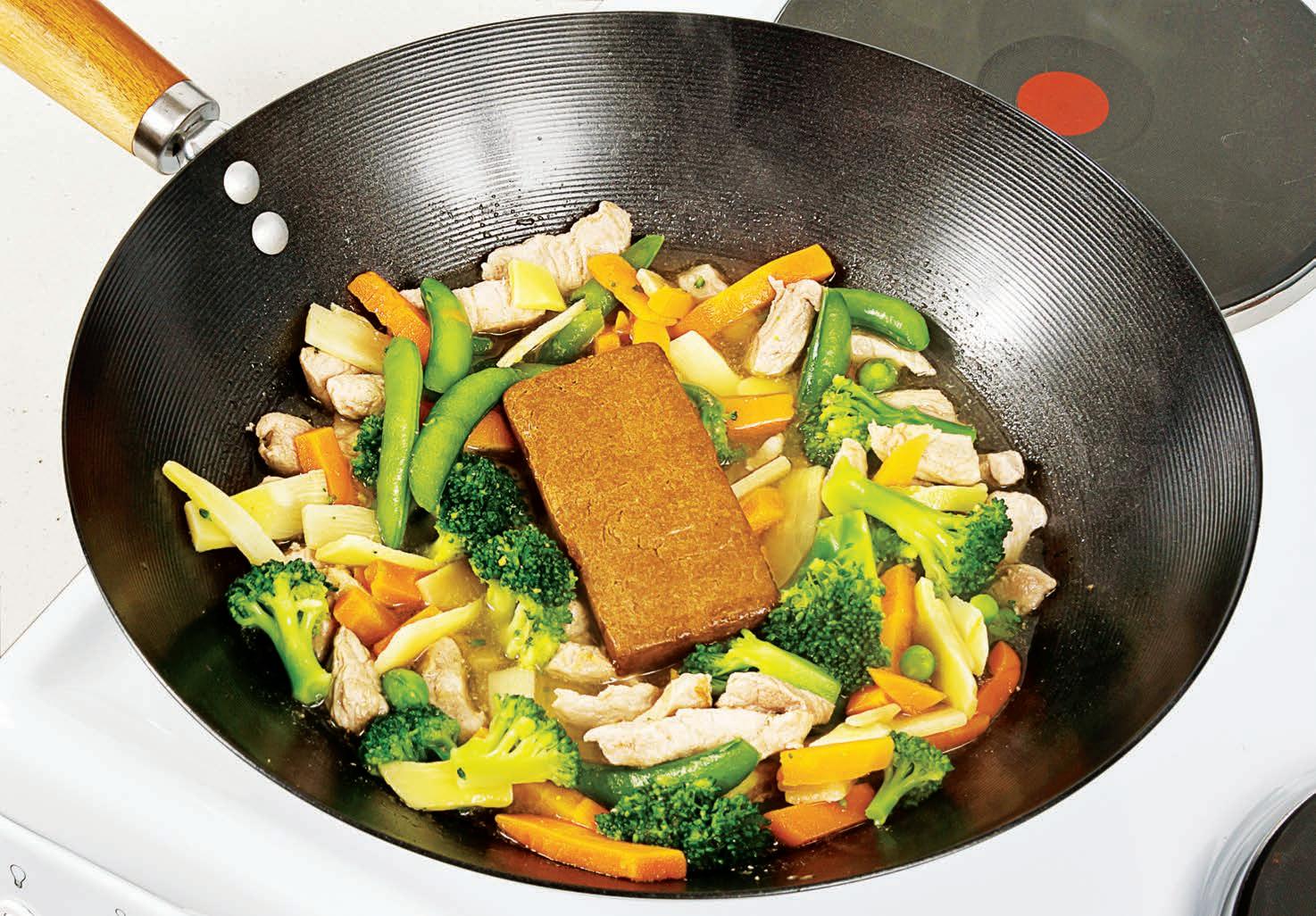

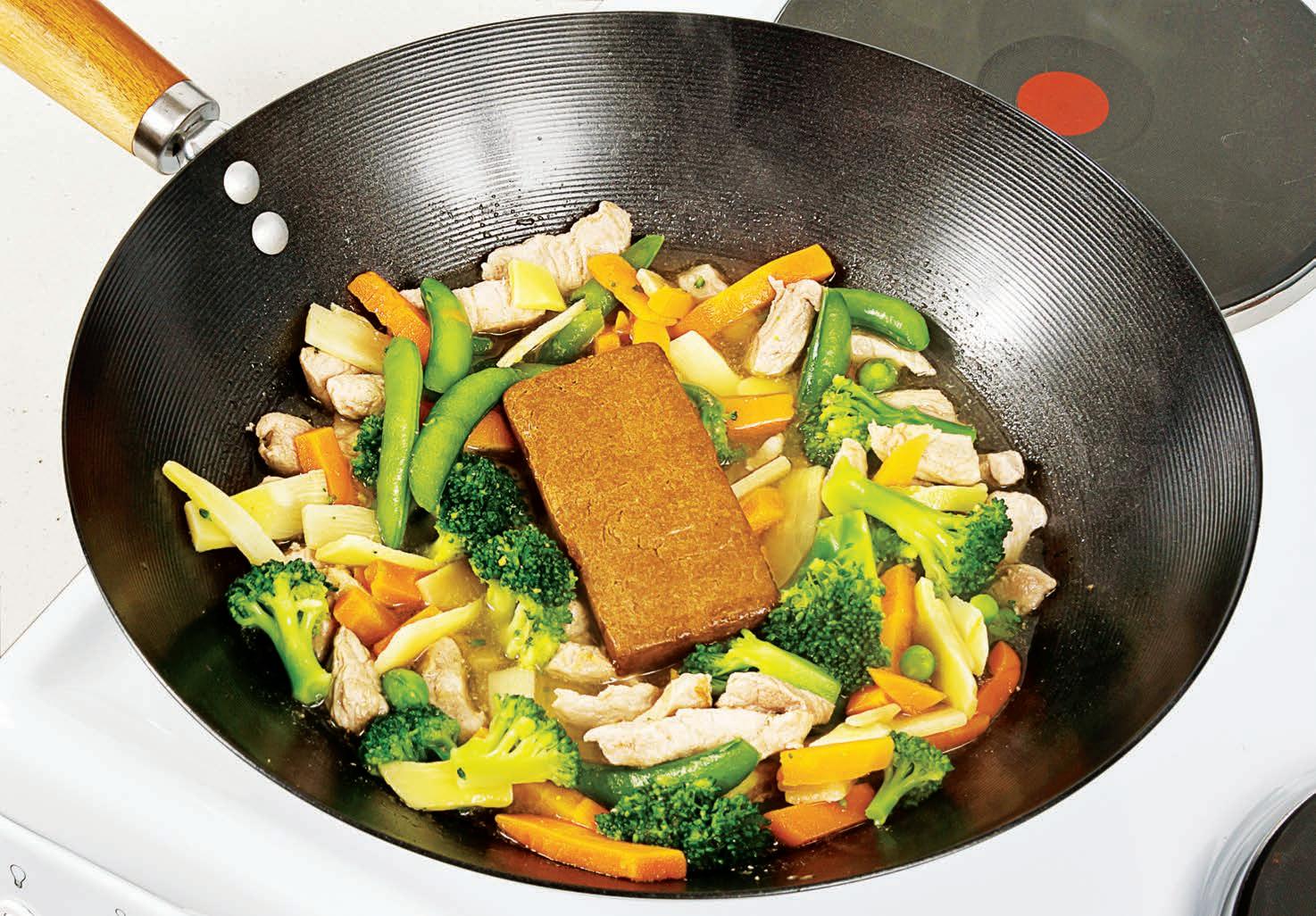

Suite 303,

1-9 Chandos Street

Saint Leonards NSW 2065, Australia

Ph: (02) 9439 7227

The important role of Australian made

TEditor: Adam McCleery

TEditor: Adam McCleery

he spotlight for this year’s May edition of Food & Beverage Industry News shines brightly on the theme of “Australian Made and Owned.”

Following a series of industry gatherings nationwide, one resounding truth echoes: while the industry remains inherently global, the significance of local manufacturing, production, and supply chains has never been clearer.

The lingering impact of the pandemic casts a shadow that still affects us today, particularly evident in global supply chains.

Wars, weather anomalies, and other unforeseen events further underscore the vulnerabilities inherent in overreliance on globalisation, a reality starkly illuminated during the pandemic’s onset.

As the world gradually inches back toward pre-pandemic import and export levels, conversations with numerous stakeholders reveal a common sentiment: a resurgence in prioritising local supply and manufacturing wherever feasible.

However, other global factors, such as military conflict, is also expected to have an ongoing impact on supply chain, meaning the return to pre-pandemic import and export levels may take some more time yet.

Again, reinforcing the importance of a robust local market and supply chain to help offset global machinations that impact on the market, and by extension, the consumer.

Coupled with evolving demands for efficiency and sustainability, the trend towards streamlining logistics whenever possible persists. Meanwhile, a shift towards localised networks promises additional advantages for stakeholders in the industry.

The industry is already rising to the occasion. Whether by achieving environmental targets ahead of schedule or spearheading initiatives like the phasing out of single-use plastics, food and beverage businesses are at the forefront of change.

This slight redirection bears numerous positive ramifications, notably benefiting both emerging and established Australian producers and manufacturers. Supermarket shelves nationwide are now adorned with products from enterprising Australian companies eager to secure their slice of the market, many capitalising on prevailing trends.

Staying attuned to emerging consumer preferences proves to be a wise strategy for manufacturers, producers, and retailers alike, particularly amidst the backdrop of a burgeoning cost-of-living crisis.

As grocery prices soar, consumers are increasingly inclined to re-evaluate their purchasing habits, opening avenues for new opportunities and innovation from food and beverage manufacturers.

The food and beverage industry thrives on innovation, and armed with insights into evolving expectations, the path to pioneering breakthroughs becomes clearer.

The industry has a storied history of adaptability, readily pivoting in response to enduring pressures.

The current landscape, characterised by cost-ofliving concerns, efficiency imperatives, sustainability goals, and shifting consumer preferences, is no exception.

The future appears bright for the Australian food and beverage manufacturing industry, provided it continues to address the evolving needs of both the industry and consumers.

As we look forward, optimism pervades, underpinned by a commitment to meeting the demands of a dynamic market.

While food and beverage is as important as electricity and plumbing to a modern society, keeping up with changing consumer demands and market expectations has, and always will be, of supreme importance.

Until next month, happy reading.

WELCOME www.foodmag.com.au | May 2024 | Food &Beverage Industry News 3

Printed by: Manark Printing

Dingley Ave Dandenong VIC 3175

28

Ph: (03) 9794 8337

20 COVER STORY: INDUSTRIAL SOLUTIONS

The story of Motion Australia spans the supply of bearings, industrial drives, motors, lifting, sealing and fluid power solutions as well as engineering services.

22 MEET THE MANUFACTURER

Bec Hardy Wines is the continuation of over 100 years of wine making expertise.

26 INSTRUMENTATION

The significance of digital connectivity and hygiene, especially in guaranteeing product quality and compliance with regulatory standards, cannot be emphasised enough.

28 PACKAGING

COPAR continues to test and innovate its growing portfolio of alternative fibre-based packaging.

30 TRACEABILITY

The Traceability Analysis Program by GS1 provides organisations with a comprehensive solution for independent traceability.

32 INDUSTRIAL GAS

Dry ice has proven highly effective in the food and beverage cold chain, along with other forms of carbon dioxide.

34 INGREDIENTS

Earlee Products remains dedicated to supplying the industry with high-quality value-added products that enhance the premium aspect of existing protein products.

36 FLOW MEASUREMENT

Bürkert offers complete solutions for breweries, aiding in the automation and digitisation of fluidic processes.

38 MICE

Tickets are on sale for the 2024 Melbourne International Coffee Expo.

40 COLD CHAIN LOGISTICS

Scully RSV is reinforcing change through its collaboration with OzHarvest, one of Australia’s largest food rescue organisations.

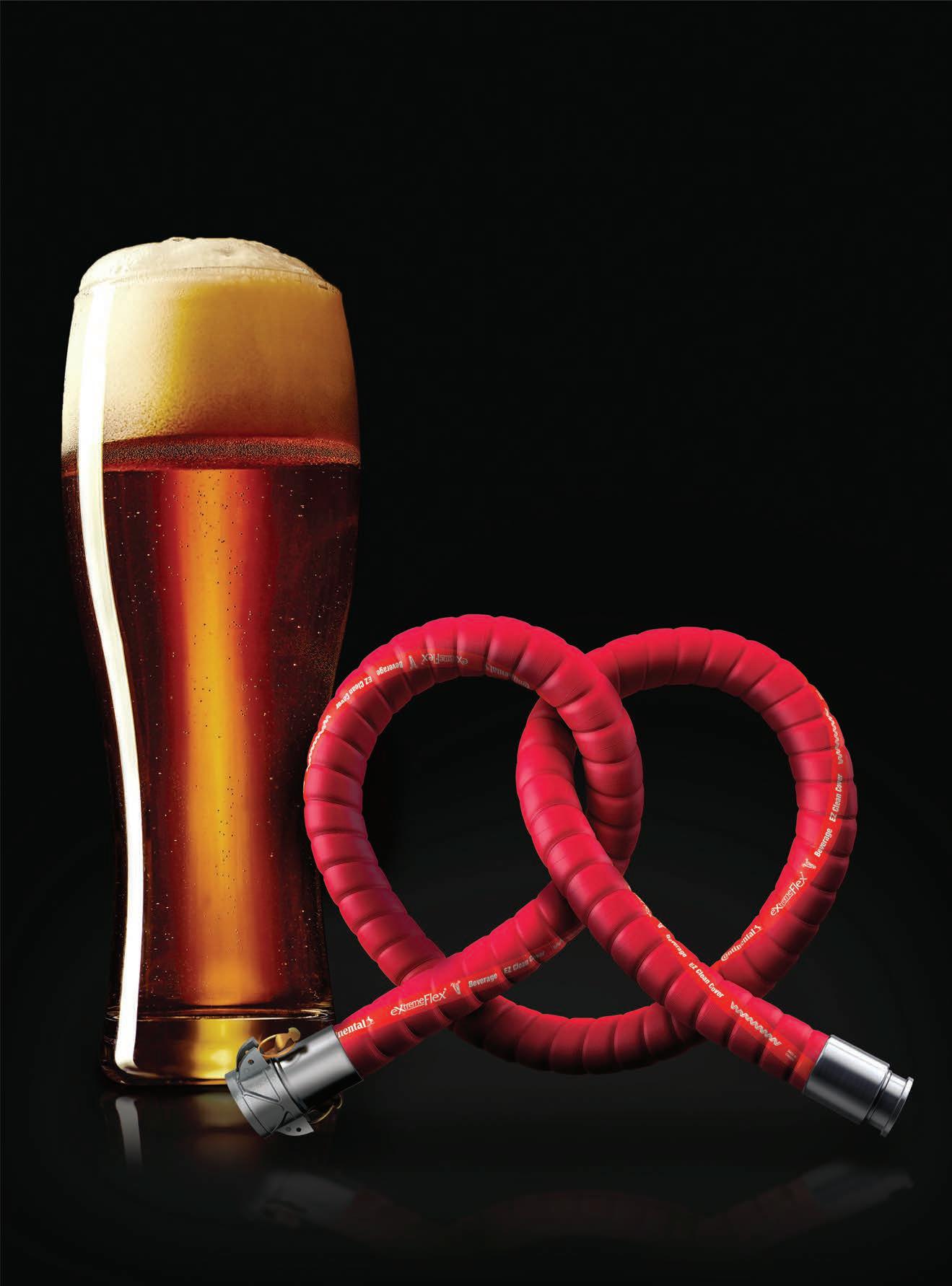

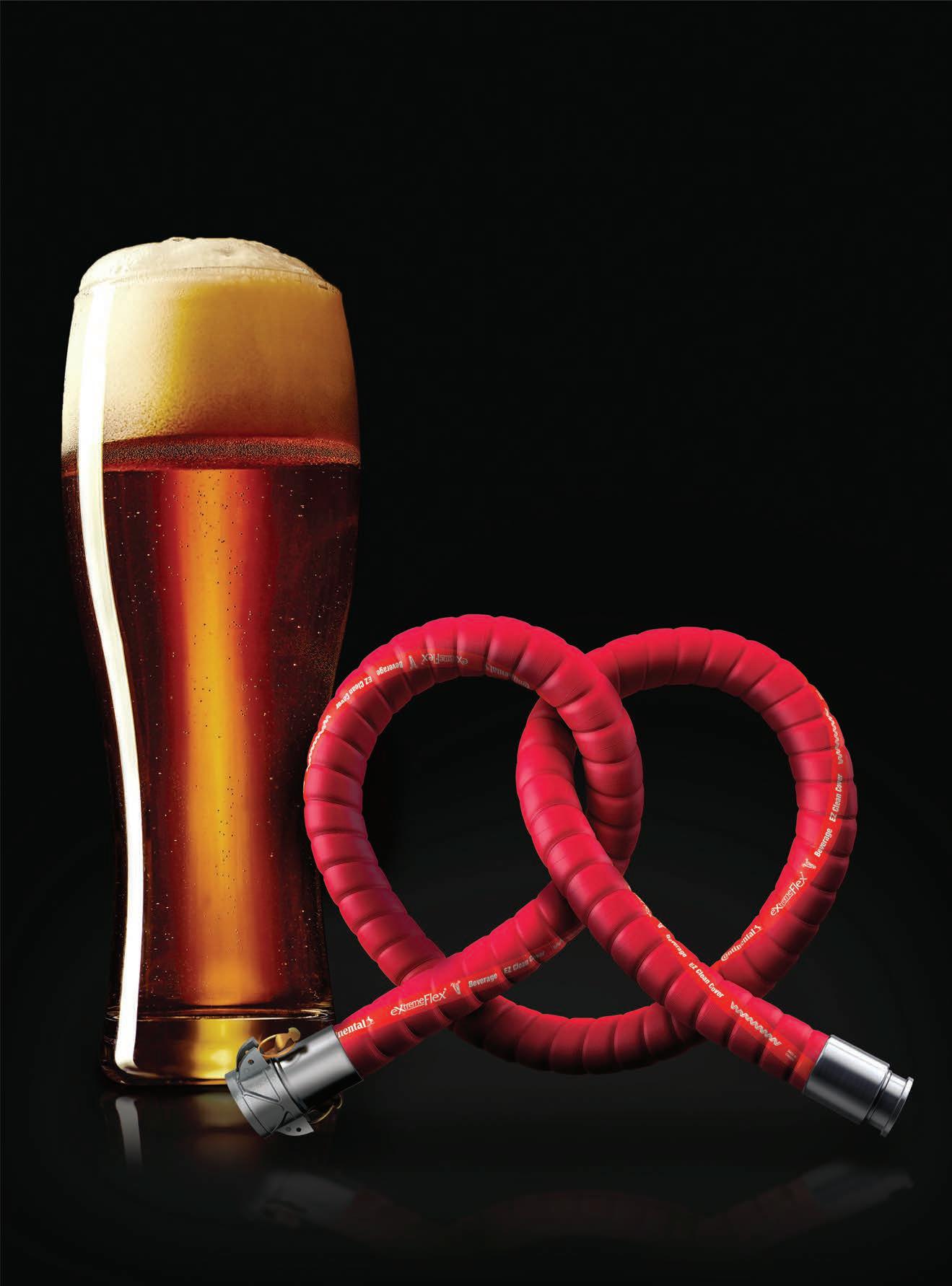

42 INDUSTRIAL HOSES

ContiTech is renowned for its innovative approach and proficiency in rubber and plastic technology.

44 AUTOMATION

QUT’s pioneering robotic arm project has the potential to transform banana farming.

46 AFGC

The National Plastics Recycling Scheme, led by the industry, aims to recycle soft plastics into food-grade packaging.

48 AIP

50 NEW PRODUCTS

4 Food &Beverage Industry News | May 2024 | www.foodmag.com.au CONTENTS 22 30 40 44 6 NEWS

Ferrero Australia awarded Canstar Blue Award

Ferrero Australia has accepted Canstar Blue’s ‘Most Satisfied Customers’ Award in the Boxed Chocolate category.

Ferrero Rocher received five stars for overall customer satisfaction as well as top marks for taste and texture.

The Canstar Blue Award is determined through a comprehensive survey of over 3,000 Australians, with more than 300 respondents confirming their purchase of boxed chocolates within the past three months.

Natalia Stewart, senior brand manager for Ferrero Rocher said, “We are honoured to receive this prestigious accolade, which underscores our unwavering commitment to excellence in both product quality and customer experience.”

Ferrero Rocher emphasises quality is at the heart of what they do, “from the careful choice of rigorously selected ingredients to the correct processing temperatures to offer a consistent taste experience for our consumers,” said Stewart.

Christine Seib, Canstar Blue’s editor-in-chief said, “Almost half of shoppers who buy boxes of chocolates say that’s their go-to choice of gift for friends and family, while more than a third believe that chocolate makes everything in life better. So, there are some heavy expectations placed on chocolatiers!”

Ferrero state this recognition arrives amidst significant growth and acclaim for Ferrero Australia. F

The Arnott’s Group supports research for recycled packaging

The Arnott’s Group is supporting the future of recycled packaging through a collaboration with Paco Industries and UNSW.

The research program looks to progress technologies in recycling, bio plastics and carbon capture to address the plastic packaging challenges that faces the food and beverage industry.

The collaboration, backed by FP Paradigm and Future Food System, utilises the UNSW Chemical Engineering department to address the challenges associated with postconsumer plastic waste and re-use of PET packaging.

The partnership also includes support from Tacca Plastics and Pablo & Rusty’s Coffee.

The Arnott’s Group chief transformation officer Simon Lowden said, “Working with Paco Industries and UNSW reflects our commitment as a business to go beyond our sustainability commitments and find innovative solutions so that The Arnott’s Group can continue to create delicious moments, not just for our consumers, but for our value chain”.

Aligned with the principles of the

circular economy, the partnership bolsters The Group’s commitment to having 100 per cent of its packaging made from materials that are capable of being recycled.

The Group has also already transitioned 86 per cent of its Australian

Paco’s technology is based on using organic solvents that can isolate PET (Polyethylene terephthalate) and has the potential to turn contaminated postconsumer PET waste back into food- grade PET for the food and beverage industry. The solvent can break down the

recycling companies and municipal councils is the level of contamination on plastic making it harder to recycle without being thoroughly cleaned.

“This technology could revolutionise our approach to recycling and redefine the materials we consider recyclable,”

The Arnott’s Group is supporting the future of recycled packaging.

NEWS 6 Food &Beverage Industry News | May 2024 | www.foodmag.com.au

Image: The Arnott’s Group

Image:

Ferrero Australia

Ferrero Rocher received five stars for overall customer satisfaction as well as top marks for taste and texture.

Queensland beef industry to benefit from $500m

Central Queensland is set to benefit from development and progressive delivery of $500 million of upgrades to priority road corridors to support Queensland’s beef industry.

Queensland is a significant global beef processor servicing domestic and global markets.

Upgrading the beef corridor network will increase productivity across the agriculture and resource industry sectors along with improving safety.

According to the Queensland state Government, in a typical year, almost 50 per cent of all Australian beef and veal products are processed in Queensland.

Queensland transport and main roads minister Bart Mellish said, “Central Queensland is Australia’s heartland for beef production.”

Queensland’s beef corridor network stretches across nearly 218,000 square kilometres and runs from east to west across Central Queensland.

This strategic web of roads carries world-class beef product and contributes $1.7 billion to the Australian economy.

The Queensland Government, in partnership with Australian Government, will work with seven local government mayors and key industry stakeholders on the identification of short, medium and long-term beef road priorities to inform a 10-year Central Queensland Beef Roads

Investment Strategy.

“The road upgrades to be proposed under a 10-year Central Queensland’s Beef Roads Investment Strategy will provide safer and more efficient transport solutions for this nationally-significant industry and increase economic opportunities for the region,” said Mellish.

To kick start the initiative, an early works package is being developed with the Queensland state Government funding contribution, to prioritise projects.

Construction is expected to commence progressively from 2024-25.

These works are in addition to the $107 million early works package announced in November 2023 to kickstart works on the $1 billion Inland Freight Route, also known as the Second Bruce.

“The Department of Transport and Main Roads will engage with relevant local governments and key industry stakeholders to develop a 10-year strategy to prioritise beef road upgrades where they are needed most,” said Mellish.

The Australian Government has confirmed its funding contribution of $400 million as part of the Mid-Year Economic and Fiscal Outlook, and the Queensland Government’s commitment of $100 million to upgrade Queensland Beef Corridors is outlined in the Queensland Transport and Roads Investment Program (2023-24 to 2026-27). F

NEWS www.foodmag.com.au | May 2024 | Food &Beverage Industry News 7 +61255656770 www.copar.eco sales@copar.eco Join Leading Brands: Customise Your Sustainable Packaging Today! Let’s start designing your Custom Packaging Fill out the form below to get started Why COPAR Our in-house team ensures your packaging is precisely what you envision Custom Fit for Your Brand Functional Eco-Friendly Uniquely Yours Perfect for… Smooth transition… Contact COPAR to join the revolution in packaging. Be a leader in sustainability. Food Service & Hospitality Ready To Eat Fresh Produce Meat And Poultry HealthCare Convert Your Plastic Packaging into COPAR’s Sustainable Wheat Straw Packaging Australian production to commence in 2024 Australian Manufacturing Choose our recyclable & compostable options Comply with Future Packaging Design Guidelines We use the latest PFAS-free oil and grease resistant technology No PFAS Added Durable and functional packaging that meets your needs and does not harm the environment Designed for Purpose

Queensland is a significant global beef processor servicing domestic and global markets. Image: Inge/stock.adobe.com

Sustainability certifications increasing in Adelaide Hills

Sustainability certification multiplies in Adelaide Hills, as Nepenthe achieved ‘B Corp’ certification in February, making it the second Adelaide Hills’ winery to do so.

There are only three wine companies in Australia that are currently B Corp certified, and these include Nepenthe at Balhannah and Unico Zelo at Gumeracha.

President of Adelaide Hills wine region Alex Trescowthick said, “Building sustainability into our region’s culture is one of our strategic objectives. In 2023 we saw three-fold growth in the number of Adelaide Hills’ members gaining Sustainable Winegrowing Australia certification.”

B Corp, which stands for Benefit for All Corporation, aims to change global culture to a better economic system in which ‘for-profit’ businesses yield benefits to people, communities, and the planet.

“We acknowledge Unico Zelo who has been an innovator in this space,

having been a B Corp for four years,” said Trescowthick.

The certification is international and involves a rigorous assessment against a set of strict impact areas.

“We now congratulate the team at Nepenthe on their newly achieved status. It’s exciting to see another certified B Corp in the Adelaide Hills wine region,” said Trescowthick.

Co-owner of Unico Zelo wines Laura Carter said, “Achieving B Corp status is challenging. B Corp broadened our understanding of sustainability to consider the impacts of our business on workers and community too.”

Nepenthe winemaker James Evers said, “By the end of 2024 we will be powered by 100 per cent renewable energy, plus, we have a responsible enjoyment partnership with DrinkWise.”

The growth of Sustainable Winegrowing Australia certified vineyards in the Adelaide Hills has

escalated rapidly in the last year from 7 in 2021/22 to 39 by 2022/23.

The proportion Adelaide Hills members of Sustainable Winegrowing Australia who have achieved certification under the program grew threefold from 14 per cent in 2021/22 to 48 per cent in 2022/23.

Alternative milk start-up raises $2.7m in seed funding

Start up AndFoods has raised $2.7 million in ‘seed’ funding for its novel technology extracting plantbased milk from seeds, led by Icehouse Ventures.

Located in New Zealand, the Palmerston North-based AndFoods uses the seeds or ‘pulses’ of a legume to create a range of allergen free, great tasting dairy alternatives, without compromising the environment.

The start-up sprung out from research at Massey University and the Riddet Institute.

Since launching as a company less than a year ago, the company has seen great momentum as it adds Leon Clement (former Synlait chief executive officer, ex-Fonterra MD) as its chair, and begins product development work with some of the largest food companies in the world.

Icehouse Ventures partner, Barnaby Marshall said, “No one is doubting the demand for dairy-free products. Consumers want them, the environment

needs them, but at the end of the day they have to stand up to the taste test.”

The extraction technology addresses the growing demand of plant based products.

“AndFoods has developed something that is poised to become a fundamental ingredient for all kinds of food producers, at a high enough quality that it’s immune to changing trends,” said Marshall.

Many dairy alternatives are capturing the taste and texture of dairy milk, AndFoods believes few have come close to emulating the measurable quality of high-grade cow-based creams or milk powders.

Originally used as an ‘orphan crop’ to regenerate soil between rice harvests, the legume at the heart of Andfoods research was a brain wave from the company’s chief technology officer and co-founder, Dr Arup Nag.

“This has been a union of the special ingredients native to my home in India,

“Acknowledging the contribution of the Sustainable Winegrowing Australia certified growers to Nepenthe’s B Corp certification rewards the efforts of many people across the Adelaide Hills to aim towards a better future for all,” said Trescowthick. F

AndFoods has used the seeds or ‘pulses’ of a legume to create a range of dairy alternatives.

combined with the resources and expertise from the team at the Riddet Institute,” said Nag.

During Massey’s investigation into new candidates for plant-based milks, Nag recalled the latent potential of a legume seed from his homeland India,

which guided the ensuing multi-year R&D efforts.

“With Andfoods we now have the means to commercialise this scientific discovery and provide the best plantbased cream and ingredients to the world,” said Dr Nag. F

NEWS 8 Food &Beverage Industry News | May 2024 | www.foodmag.com.au

Image: ArtSys/stock.adobe.com

There are only three wine companies in Australia that are currently B Corp certified.

Image: John Krüger

Detpak wins national award for packaging design innovation

South Australian packaging company Detpak received the APPMA Packaging Design Innovation Award for its kerbside recyclable paper bag for fresh potatoes.

The APPMA (Australian Packaging and Processing Machinery Association) Awards of Excellence 2024, held in Melbourne, is the national awards program for the Australian packaging and processing industry and recognises excellence, innovation, leadership and best practice.

Detpak, a subsidiary of the South Australian third-generation familyowned Detmold Group, has been recognised for developing what is believed to be Australia’s first kerbside recyclable paper bag for fresh potatoes, in collaboration with national leading potato and onion producer Mitolo Family Farms and Coles.

Detpak is aiming to replace all 100 per cent plastic packaging in fresh produce and help set the stage for

industry-wide transformation.

Detpak sales general manager Roman Bolzon said “Detpak is proud to be part of a collaborative groundbreaking packaging design solution that is leading a broader shift towards sustainable practices in the grocery sector as consumers become more environmentally conscious,”

The paper-based bag was launched last year following three years of rigorous development, transforming fresh potato packaging for Mitolo’s Gourmandine potato range, reducing plastic usage by 64 per cent, equating to 8.2 tonnes less plastic each year.

“Detpak is proud to be part of a collaborative ground-breaking packaging design solution that is leading a broader shift towards sustainable practices in the grocery sector as consumers become more environmentally conscious,” said Bolzon.

Detpak’s RecycleMe technology

Detpak has been recognised for developing what is believed to be Australia’s first kerbside recyclable paper bag for fresh potatoes.

maintains product quality, extends shelf life, and offers kerbside recyclability, aligning with Australian Packaging Covenant Organisation guidelines.

“We are always looking at innovative

ways to drive sustainable change across the packaging industry and are continuing to evolve packaging to be better for our environment,” said

NEWS www.foodmag.com.au | May 2024 | Food &Beverage Industry News 9

Bolzon. F

Image: Detpak

Action plan to reduce fruit and vegetable food waste

End Food Waste Australia in collaboration with the Australian Bananas Growers’ Council, Melons Australia, and the horticulture industry have released a new nation-wide plan to help save fresh produce and halve Australia’s food waste by 2030.

According to End Food Waste Australia, fruits and vegetables are Australia’s most wasted foods.

New action plans have been developed to tackle horticulture food waste, identifying the nine priority actions to reduce food waste from farm to retail.

The Horticulture Sector Action Plan provides an Australian-wide view of key horticulture food waste root causes and identifies the most impactful actions to reduce food waste.

“Reducing horticulture food waste is critical to reaching Australia’s goal of halving food waste by 2030 and will have positive impacts for everyone,” says Dr Steven Lapidge chief executive officer of End Food Waste Australia.

The nine key action areas identified in the plan aim to reduce fresh produce

food waste that occurs at every stage of the food supply chain, on farm, during transportation and manufacturing, and in retail stores.

Interventions include improving food waste data and measurement, exploring whole crop purchasing arrangements, reviewing product specifications, improving logistics to get fresh produce to food rescue charities, investing in and growing value-add opportunities and Australia’s upcycled foods market, such as freeze-dried fruits, vegetable powders and many more.

The most impactful interventions depend on the produce type, End Food Waste Australia state bananas and melons have led the way with dedicated Food Waste Action Plans and targeted priority actions.

“The horticulture industry, with leadership from the bananas and melons industry and support from Queensland Government and Hort Innovation Australia have come together to demonstrate collaboration on sustainability leadership in the

A new nation-wide plan to help save fresh produce and halve Australia’s food waste by 2030 has been revealed.

development of these plans,” said Lapidge.

Leon Collins, chairman of the Australian Banana Growers’ Council said the Australian Banana Growers’ Council were proud to be at the forefront of the horticulture industry in finding solutions to reduce banana food waste.

Johnathon Davey, executive officer of Melons Australia and the Australian melon industry said, “This plan is strategic and presents a way forward and significant growth opportunities for our growers, for the melon industry, for all

Reducing dairies waste by upcycling whey in a new beverage

Arla Foods Ingredients has launched a fermented beverage concept that demonstrates how dairies can reduce waste and increase yield by upcycling whey.

According to Arla Food Ingredients raw material waste is a major problem for dairies. After processing, many are left with large whey side streams, which can cause environmental damage if discharged with wastewater.

Ignacio Estevez, application manager, South America at Arla Foods Ingredients said, “Consumers hate the idea of waste, especially if it’s environmentally harmful. Reflecting this, we’re starting to see more and more products that make use of upcycled ingredients and communicate it on their packaging.”

Arla Foods Ingredients has launched

a fermented beverage concept based on upcycled acid or sweet whey. It also contains Nutrilac whey proteins, which they state provides a light texture and refreshing taste, as well having a protein content as high as 8 per cent, meaning a 200ml bottle would contain 16g of protein.

“Getting value out of whey is a significant challenge in dairy production but, as this concept demonstrates, it can be used to create on-trend new products that appeal to both sustainabilityconscious and protein-focused consumers,” said Estevez.

The company stated that sustainability is a growing focus in Latin America, with over 50 per cent of consumers in the region saying they have changed their behaviors based on environmental concerns, a figure

Australians and the environment.”

Davey said, “We acknowledge that by reducing food waste we create opportunities to improve grower and the broader supply chains profitability, reduce the environmental footprint of food waste and assist those Australians experiencing food insecurity.”

The Horticulture Sector Action Plan, Banana Food Waste Action Plan and Melon Food Waste Action Plan are available at www.endfoodwaste.com.au/ horticulture F

projected to reach 70 per cent by 2025.

Arla Foods Ingredients is showcasing the new concept in a series of videos,

highlighting its benefits including the sustainability, technical, regulatory, and consumer trends perspectives. F

NEWS 10 Food &Beverage Industry News | May 2024 | www.foodmag.com.au

Arla Foods Ingredients has launched a fermented beverage concept based on upcycled acid or sweet whey.

Image: Arla Foods Ingredients

Image: ArieStudio/stock.adobe/com

The Aquaculture Stewardship Council (ASC) and the Marine Stewardship Council (MSC) unveiled the annual Sustainable Seafood Awards winners at the launch of the Super Seafood campaign to raise awareness about ASC and MSC certified seafood.

The Sustainable Seafood Awards Australia are independently judged and recognise organisations and individuals who contribute significantly to ensure a long term fish supply by committing to the ASC and MSC programs.

• Coles was named the MSC’s Best Sustainable Seafood Supermarket, and the ASC awarded ALDI the Best Responsible Seafood Retailer title.

• MSC’s Best Sustainable Seafood Product - Shelf went to John West Salmon Bowls.

• I&J was named ASC’s Best Responsible Seafood Brand

• Birds’ Eye Frozen Steam Fresh Fillets took the ASC’s Best Responsible

Recognising Australia’s sustainable seafood market Developing Victoria’s distillery industry

Victorian distillers have the opportunity to benefit from a new pilot training program that is focused on distillation techniques and industry safety.

The $1.2 million pilot education pathway for distillers is being delivered by the National Distilling Institute in collaboration with the Spirits Victoria Association and the Australian Distillers Association.

The initial courses will be a Certificate IV in Artisan Fermented Products and micro-credential courses for safety in distilleries.

Minister for Agriculture Ros Spence said, “We’re investing in the future of distilling and we are thrilled to be partnering with industry leaders to deliver this new course that will set Victorian distillers apart from the rest.”

The first session was held at Starward Distillery in Port Melbourne,

Seafood Product award home.

• A special Lifetime Achievement was presented to the Department of Primary Industries and Regional Development Director General Heather Brayford for her outstanding contribution to sustainable fisheries management in Western Australia in a career spanning 35 years.

Anne Gabriel, MSC program director said, “The commitment of brands and retailers to source and sell ASC and MSC certified seafood sends a clear signal down the supply chain and incentivises sustainable fishing and responsible aquaculture practices.

Globally, there are 1800 ASC-certified farms, 550 MSC-certified fisheries, and over 46,000 products with the ASC and MSC labels.

Duncan Leadbitter, ASC commercial manager said, “We’re encouraged to see real progress made in the last year by leading brands and retailers in moving to ASC and MSC-certified seafood.”

quality, and responsible sourcing Charlotte Rhodes said, “We’re driven to help our customers better understand the potential environmental impacts of the products they purchase. The transparency that comes from the MSC blue fish tick label helps customers make more informed and sustainable choices

Daniel Baker, ALDI’s national sustainability director said, “It’s fantastic to receive recognition from the Aquaculture Stewardship Council for our responsible fish and seafood sourcing.

The awards recognise Australia’s progress towards sustainable seafood. F

the following sessions will occur at regional distilleries in Geelong, Ballarat, Mornington and the High Country throughout April.

Member for Albert Park Nina Taylor said, “It’s great to see top industry bodies coming together to nurture and empower the next generation of distillers.”

Over the next 18-months, the first round of students will complete up to 22 different subjects where they will gain expertise in areas ranging from how to blend spirits and filter fermented beverages, to how to perform basic safety tests and control food contamination and spoilage.

Victoria has more than 180 distillers that employ over 9,000 people across regional and metropolitan Victoria.

Spirits Victoria Association President David Irwin said, “Victorian spirits are already globally renowned for the awards

Victorian distillers are invited to a new pilot training program that is focused on distillation techniques and industry safety.

they have won on the world stage, but we believe further skills development is vital to safeguarding our industry‘s future.”

This program is part of the $20 million Distillery Door Program which

promotes Victoria’s distilling industry through supporting skills development, boosting visitor economy, improving infrastructure and safety, and increasing export capability. F

NEWS www.foodmag.com.au | May 2024 | Food &Beverage Industry News 11

The annual Sustainable Seafood Awards winners revealed.

Image:

Raul

Machin Image:PictureArt/stock.adobe.com

Ortiz de Lejarazu

Nestlé pursing better packaging solutions and waste management

Nestlé’s vision is that none of its food and beverage packaging ends up in landfills or as litter.

The food and beverage company highlights how it is improving its packaging to facilitate recycling and how it is supporting better waste management.

At the end of 2023, 83.5 per cent of Nestlé’s plastic packaging globally was designed for recycling.

Nestlé’s Head of ESG strategy and deployment Antonia Wanner said, ““We are making progress in reducing our overall packaging, making it more recyclable, and using renewable or recycled materials in our packaging.”

For recyclable packaging materials to actually be recycled, a scale up of waste management infrastructure is needed.

Nestlé is working with local and national governments, industry alliances, civil society and consumers to develop and improve recycling infrastructure in the countries where it operates.

“The design of, and material used in, our packaging are factors we can directly impact. But we also go beyond that and help build up waste management infrastructure, support harmonized regulation, and engage on the human rights of waste workers,” said Wanner.

Nestlé has partnered on 220 initiatives to develop well-functioning waste collection, sorting and recycling schemes in Europe, Africa, Asia, North America and Latin America.

Nestlé also uses recycled and renewable materials in its packaging, and at the end of 2023, 41.5 per cent

of its total packaging was made from recycled or renewable content. Nestlé is continuing to pursue its

work to keep packaging materials in the circular economy, and out of the environment. F

Government inquiry into growth opportunities for food and beverage manufacturing

The House of Representatives Standing Committee on Industry, Science and Resources will inquire into opportunities for innovation and growth in the food and beverage manufacturing industry in Australia.

Food manufacturing is the largest sector in Australia’s manufacturing industry, employing more than 20 per cent of all manufacturing workers.

Parliament Australia stated governments have long recognised the sector’s export growth potential, given Australia’s established reputation and trade relationships as a top exporter of high-quality agricultural produce.

Committee Chair Rob Mitchell MP said the food industry was on the cusp of great opportunities as well as challenges.

‘Australian scientists and food manufacturers are making inroads into high-tech emerging sectors and developing new high value-added products built on our world-class agricultural sector,” Mitchell said.

“They are adopting process innovations to make traditional food

A Committee will inquire into opportunities for innovation and growth in the food and beverage manufacturing industry in Australia.

and beverages tastier, safer, cleaner and more productive.”

of innovation in the industry, Mitchell said, “the inquiry will examine the state of innovation in the industry, including new technologies for post-farmgate food and beverage manufacturing and packaging, and opportunities for growth in new product markets.”

beverage industry.

‘We want to hear from large and small manufacturers about their experiences, hopes and fears for the future,” Mitchell said.

submissions addressing any or all of the inquiry terms of reference by Wednesday 1 May 2024. The terms of reference and additional information on the inquiry can be found on the Committee’s website. F

NEWS 12 Food &Beverage Industry News | May 2024 | www.foodmag.com.au

Image: dusanpetkovic1/stock.adobe.com

Image: dusanpetkovic1/stock.adobe.com

Nestlé highlights how it is improving its packaging to facilitate recycling better waste management.

Hygienic flow meter with IO-Link Completes the food digitalisation portfolio

Eliminate blind spots in your digital process!

Equipped with IO-Link, the newly released SM Foodmag magnetic-inductive flow sensor from ifm takes the flow measurement of food products – such as milk, wine, juice – to a new level. It is the first of its kind to enable digital data transmission from the process, removing the last blind spot from the F&B production process.

Key benefits and features

Efficient: Provides flow rate, total volume, temperature and conductivity.

Hygienic: Rated with IP67 and IP69K.

Accurate: Error-free connection to data infrastructure.

Robust: Has undergone rigorous pressure, shock, temperature and condensation testing.

Easy set-up: App-based menu and guided installation.

Expert support: Our team of experienced F&B product engineers will ensure you get the maximum benefit from this digital solution.

Need help with digitalisation? Let us assist. We draw on a wealth of global expertise to provide you with the best local support. 1300 365 088 I sales.au@ifm.com I www.ifm.com/au

Queensland reaches milestone in Containers for Change scheme

Eight billion containers have now been returned through the Queensland State Government’s Containers for Change scheme.

Environment Minister Leanne Linard and Container Exchange CEO Natalie Roach celebrated the latest milestone at the Community Co Recycling Depot in Windsor on Brisbane’s northside.

The Containers for Change scheme was launched in November 2018 and provides 10-cent refunds for eligible drink containers.

“This is a phenomenal amount of waste that has been diverted from landfill and instead recycled and reused thanks to our Containers for Change scheme. This is great news for our unique natural environment,” said Linard.

The government state the scheme has continued to grow from strength to

Queenslanders have returned eight billion containers through the Queensland State Government’s Containers for Change scheme.

strength.

“It is really exciting to see how our container refund scheme continues to grow and I congratulate Queenslanders for their ongoing efforts to return containers and receive a refund,” said Linard.

It has taken just six months to reach this latest milestone, after the seven

billionth container was returned in September 2023.

A record 175,805,461 containers were returned in January alone, surpassing the previous record of 157.5 million achieved in January 2023.

In an Australian-first, the Queensland scheme was expanded in

CSIRO invests $20 million to boost SME innovation

CSIRO, Australia’s national science agency, announced a $20 million investment aimed at granting small to medium enterprises (SMEs) enhanced access to crucial

CSIRO announced a $20 million investment aimed at granting small to SMEs enhanced access to R&D resources.

research and development (R&D) resources.

The funding will allow CSIRO’s SME Connect team to support up to 750 SMEs through a range of programs

and initiatives that provide facilitation, training, dollar-matched funding and support to start-ups and SMEs seeking to engage in company-led research projects.

Dr Doug Hilton, CSIRO’s chief executive said, “SMEs are crucial drivers of Australia’s future and so often the engine room of new, innovative thinking and solutions to many of the challenges our society faces.”

This program will aid businesses across sectors such as technology, manufacturing, health, and biosecurity to accelerate their growth and scale.

“CSIRO’s fundamental role as the national science agency is to create benefits for Australia and that includes helping to drive SME’s productivity, sustainability and growth through greater access to R&D opportunities and conducting research to support a more resilient and diverse economy,” said Hilton.

Minister for industry and science Ed Husic praised the announcement and

November 2023 to allow glass wine and spirit bottles to the returned.

Natalie Roach, chief executive officer of Container Exchange said, “With Containers for Change now including glass wine and spirit bottles, more and more Queenslanders are taking part.”

Since then, the scheme has recorded a 13.5 per cent increase in the quantity of glass bottles being returned.

“Customers can simply download the Containers for Change app to keep track of their refunds and select their preferred container refund point from depots, 24-hour bag drops, self-serve reverse vending machine kiosks and free home collection,” said Roach.

Queenslanders who have returned eligible containers have shared in $800 million in refunds. This includes around $12 million paid to charities and community groups. F

along side Hilton visited a successful Kick-Start program alumni in Canberra to witness the progress achieved through its collaboration with CSIRO researchers.

Husic said, “Our Future Made in Australian plan, whether it’s our $15 billion National Reconstruction Fund or our $392 Industry Growth Program, means there’s support for businesses big and small to make more things here.”

CSIRO stated SMEs are the backbone of Australia’s economy, constituting 99.8 per cent of businesses, contributing to more than half to the gross domestic product (GDP) and employing 68 per cent of the private sector workforce.

The SME Connect programs include:

• C SIRO Kick-Start;

• I nnovate to Grow;

• R ISE Accelerator:

For more information visit the CSIRO website. F

NEWS 14 Food &Beverage Industry News | May 2024 | www.foodmag.com.au

Images: Dragan/stock.adobe.com

Images: chokniti/stock.adobe.com

China lifts tariffs on Australian wine

The Australian Federal government welcomes the lifting of China’s wine tariff, which comes at a critical time for the Australian wine industry.

The re-entry of Australian bottled wine into the Chinese market will benefit both Australian producers and Chinese consumers.

The Federal government state this outcome affirms the calm and consistent approach taken by the government and follows the success of the similar approach taken to remove duties on Australian barley.

The government said they acknowledge and thank Australian grape growers and wine producers for their fortitude and support during a challenging period.

According to the Federal Government, Australia’s wine exports to China were worth $1.1 billion in 2019.

The Western Australian government has also welcomed the decision and will support wine exporters to re-engage in Chinese market.

The WA state government state they have worked closely with the wine industry and Wines of Western

The Australian Federal government welcomes the lifting of China’s wine tariff.

Australia through the Wine Industry Export Growth Partnership to drive wine export competitiveness and increase the value of WA wine exports.

The partnership is supported by industry funding of $3 million, matched with State Government funding of $3m, over a 4-year period.

Western Australian premier

Roger Cook said, “WA wines are world renowned, and I’m pleased that producers will now be able to re-engage with this important market.

In coming months, the partnership will assist WA wine exporters to re-establish key relationships and sale channels in China.

“We will continue to work with them

Chobani Australia appoints new managing director

Chobani, a global food and beverage company, has announced the new appointment of Scott Hadley as managing director for Australia and New Zealand.

Joining Chobani’s global executive leadership team, Hadley will report to Kevin Burns, Chobani president and chief Operating Officer.

“The Australian team has built an incredible organisation and culture and I’m looking forward to building on these great foundations and continuing to disrupt the industry and drive this business and category forward,” said Hadley.

Prior to joining Chobani, Hadley was chief executive officer at TasFoods, an ASX-listed diversified food and beverage business. He has also held senior roles

to re-establish key relationships and promote their products in China,” said Cook.

The federal government state trade diversification is a key element of the Government’s trade policy strategy and they will continue to support Australian businesses to sell their world-class products on the global stage. F

at Asahi Beverages, TT-Line Company, Fosters Group, GlaxoSmithKline and Cadbury Schweppes.

“As we thought about the leader we needed, it’s clear Scott is the natural choice to lead the team in this next phase of our journey.”

“He shares our passion for innovation, positively impacting humanity, and he believes deeply that food can and should be a force for good. We are thrilled to welcome Scott into the Chobani family,” said Ulukaya.

Hadley is a member of the Australian Institute of Company Directors, holds an Executive MBA from Australian Graduate School of Management, is a Certified Practising Accountant and has completed the Senior Executive Program at London Business School. F

NEWS www.foodmag.com.au | May 2024 | Food &Beverage Industry News 15

Images: Pixel-Shot/stock.adobe.com

Prior to joining Chobani, Hadley was chief executive officer at TasFoods.

Image: Chobani

ATO guidance for businesses supplying food and beverage products

The Australian Taxation Office (ATO) has made key changes to assist businesses in identify combination foods and understand when GST needs to be charged.

They have recently published a final Goods and Services Tax determination to help businesses identify when a supply of food is taxable, where it includes both GST-free and taxable components.

In addition they have also updated the Detailed Food List (DFL) Public Ruling.

The ATO have done this to align with the determination, provide more certainty, promote transparency and ensure a level playing field for all businesses.

The ATO’s recent updates include:

• Adding and updating entries that were identified as a priority through industry feedback adding new entries to reflect it views in recent advice and compliance activities, such as:

- water, where alkaline or other additives are added

- yoghurt with breakfast cereal, where the yoghurt and dry cereal are in separate compartments of the one product

- popping pearls that are added to beverages such as bubble tea

- sport or energy gels

• Updating 304 food and beverage product entries to better explain why they’re GST-free.

The ATO stated they are currently updating the GST food and beverage

search tool to reflect these updates to the DFL Public Ruling.

Whilst this occurs, the ATO have advised business to use the DFL list to check whether GST applies to food or

The ATO has made key changes to assist businesses in identify combination foods and understand when GST needs to be charged.

beverage products.

The ATO believe this is the easiest way to help businesses work out if GST applies on the sale price of their item, to ensure business get it right from the very start. F

CELSIUS and Suntory Oceania agreement to expand energy drink market

Celsius Holdings, Inc, maker of the CELSIUS energy drink brand, announced its expansion into Australia and New Zealand, to boost global sales and distribution.

CELSIUS and Suntory Oceania enter into definitive manufacturing, sales and distribution agreement.

John Fieldly, Celsius Holdings, Inc. chairman and chief executive officer said, “We’re pleased to introduce our refreshing, great tasting and functional CELSIUS energy drinks to consumers in Australia and New Zealand.”

CELSIUS has selected Suntory Oceania as its exclusive manufacturing, sales and distribution partner in Australia and New Zealand.

“We expect to continue our international growth at a measured pace, targeting strategically important energy drink markets and employing our proven playbook to build a strong and passionate consumer base,” said Fieldly.

CELSIUS previously announced a sales and distribution agreement with Suntory Beverage & Food Great Britain and Ireland, and sales in those markets are expected to begin in the second

quarter of 2024.

“As we build Suntory Oceania, we are delighted to be partnering with CELSIUS to evolve our portfolio and deliver new growth opportunities for all retail partners,” said Darren Fullerton, chief executive officer of Suntory Beverage & Food Oceania.

“We are excited to launch our strategic plan in Q4 2024 across the retail landscapes of Australia and New Zealand, and we look forward to accelerating growth in 2025,” said Tony Guilfoyle, Celsius Holding Inc. chief commercial officer. F

NEWS 16 Food &Beverage Industry News | May 2024 | www.foodmag.com.au

Images: ymgerman/stock.adobe.com Images: CELSIUS

Celsius Holdings, Inc announced its expansion into Australia and New Zealand.

Find it at HoseSelect.com or call 1300 RUBBER

Thirsty Group, a local Melbourne business, announced it has achieved global recognition as one of the most awarded spirits producers worldwide.

Thirsty Group announced their flagship product, Baxter Vodka, is recognised as the world’s most awarded Vodka of 2023, having won the prestigious ‘Triple Still’ Award.

Additionally, Aubrey Liqueurs earned the title of World’s Best Liqueur for Mango at the 2023 SIP Awards in Los Angeles.

The group announced Baxter Vodka has claimed the title of World’s Best Vodka on multiple occasions, most recently at 2021 Vodka Masters in London, 2022 International Spirits Competition in Berlin and the 2023 Triple Still Prize and the 2024 London Spirits Competition.

Thirsty Group’s state its portfolio has now grown to also include Tequila,

Melbourne spirit producer receives global recognition Government makes changes to Investment NSW operations

NSW Premier Chris Minns has announced a shift in focus, with industry, innovation, trade, and investment functions moving to the forefront of government operations, facilitated by the relocation of Investment NSW to the Premier’s Department.

The state government believe this transfer will make it easier for industry, investors, and entrepreneurs to participate in major government priorities and ensure seamless co-ordination across government.

The transfer brings management of proposals back to central government.

In addition, the state Government announced changes will be made to Department of Enterprise, Investment and Trade, to provide a renewed focus on government priorities in the arts, hospitality, tourism and the night-time economy portfolios, as well as driving the implementation of key reforms, including

Gin and Spiced Rum with 28 gold medals across international competitions in the past 3 years.

Having started the business out of a garage in 2017, high school friends Jake Gautreaux and Dom Evans are producing over 1 million bottles annually out of their Melbourne production facility and have achieved 8 figures in sales.

Founder Jake Gautreaux said,” Receiving the industry’s most prestigious award is a true honour, showcasing the passion and dedication of our team. We are beyond excited to continue producing World Best spirits and propel into 2024 with some exciting new variations.”

Baxter Vodka and the rest of the Thirsty Group portfolio is available online and nationwide at Liquorland, First Choice and other leading liquor stores. F

NEWS 18 Food &Beverage Industry News | May 2024 | www.foodmag.com.au

Image: chachamp/stock.adobe.com

Image: Thirsty Group

The transfer brings management of proposals back to central government.

Thirsty Group’s state its portfolio has now grown to also include Tequila, Gin, and Spiced Rum.

// Discover why F&B prefer to partner with us >

Revolutionise your production with 100% standardised automation

More choices and more solutions with consolidated Motion

The story of Motion Australia begins over a century ago, spanning the supply of bearings, industrial drives, motors, lifting, sealing and fluid power solutions as well as engineering services. Food & Beverage Industry News reports.

Leon Stefanec, national product development, Motion Australia, said with an extensive selection of products, expertise, and branches nationwide, the company is living out its promise to provide Australian industrial businesses with ‘more choices, more solutions’.

Stefanec works closely with food and beverage manufacturers in the Australian and New Zealand markets and has heard first-hand the benefits that come with working with a global company like Motion.

“What our customers tell me is they like that they can buy a wide range of products form Motion which helps reduce the number of suppliers that they have,” he said.

“We have around 130 branches and when you can pull that strength together it becomes very powerful.

“With that national footprint, and particularly now that we have become Motion Australia, is that we are looking to replicate what we do well right across the country.”

Stefanec also said the buying power Motion has built is another key reason why it’s commercially beneficial for companies to work with Motion.

Among Motion Australia’s specialities are bearings, power transmission, fluid power, and engineering services. All of which play critical roles in the food and

says Ryan Kendrigan, executive general manager of Engineering Services at Motion Australia.

“Each business within the Motion family comes with its own specialty. What’s advantageous is that with all these businesses and their specialties consolidated, our customers have an incomparable breadth of offer.”

Stefanec said one of the most talked about benefits of working with Motion was the ‘one stop shop’ aspect the company continues to build.

“The customer only needs to make one phone call or one email, which is to me, and I can bring in the right person with the right expertise,” he said.

“Whether that be someone from our workshop to discuss plastics, or an engineer, it extends to several areas.

“For the customer to know they can contact one supplier and get access to a wide range of solutions at a competitive rate means a lot to them.”

Under each of these businesses is a vast inventory of branded products –totalling over 600,000 individual items – which is supported by a network of over 1600 employees, 180 branches, 30 repair and service facilities and eight dedicated distribution centres.

As a result, Motion continues to build a strong reputation in the food and beverage manufacturing industry for its wide variety of cutting-edge solutions.

which are easily transferrable to the Australian and New Zealand food and beverage manufacturing industries.

“I often work with some large corporate accounts and some of them have got presence in foreign markets, so when we say we are a global company it really means a lot to our customers,” he said.

“If we are servicing a much larger operation overseas then that helps create confidence for potential partners here in Australia.”

In recent decades Motion shifted its focus from being a supplier of componentry to being a full solutions provider after working so closely with key industry stakeholders.

The insight Stefanec has built up over his years working with the industry has also given him the insight to provide the right solution at the right time.

“Some of the biggest priorities for food plants are in keeping production going and food security,” he said.

“Those are among the many reasons why it’s very important to be sending out high-quality components that will last and have all the required certifications,” he said.

“We have the right understanding of those products to make the correct recommendations to fit their

requirements. It’s all about service and keeping their plants up and running.”

Meanwhile, Stephen Forbes, executive general manager of Fluid Power Solutions at Motion Australia, says that Motion’s approach is still fundamentally a familybusiness – which is essential to the company’s evolution.

“For most of our history, we’ve operated as a group of family-owned companies and this heritage is reflected in the approach we take today, which is relationship focussed,” said Forbes.

“And our customers are looking to us to make it easier for them. They trust us, the brands that we supply, and the expertise we have to now provide fullservice solutions.”

As executive general manager for Industrial Solutions, Nick Kerwin says the consolidation of the company’s core businesses has only had positive implications for customers.

“We’ve worked with many of our bearing and power transmission suppliers for decades and have built on a wealth of expertise both in partnership with suppliers and in our own team,” he said.

“Being able to go to industrial businesses with a holistic offering – that incorporates everything from traditional rotating componentry to hydraulics,

MOTION CONTROL

National business development manager, Leon Stefanec, works closely with food and beverage manufacturers for Motion Australia.

Images: Motion Australia

Motion’s strong buying power makes the company a commercially beneficial partner.

hoses and fittings to bespoke engineering services, training, and even energy efficiency reviews, is hugely beneficial.”

A key example of Motion’s commitment to building its solution offerings, particularly around industrial hose fitting and fluid power, is in its string of key acquisitions over the past two years.

“The largest was Powell Industrial, which really bolstered our stock profile, inventory, workshops with bespoke hoses, and expertise,” said Stefanec.

“And the calibre of a lot of the people we have in that team is incredible.”

Engineering growth

The Motion family also includes longestablished businesses such as BSC.

“We started out as a bearing company that provided engineering support for traditional rotating equipment,” said Kendrigan.

“Now we can look at anything that’s operating in rotary motion, linear motion or hydraulic motion and provide a turnkey solution that will maximise the efficiency and output of that equipment.”

Having such a broad range of

expertise means that the Motion engineering team can come up with a process for a challenging situation.

“It’s being able to offer that turnkey solution. We can design a concept, manufacture a concept, install it, maintain it. It’s a full-service offering,” he said.

“We’re constantly looking at how we can better support our customers in Australia, and actively expanding our offering and capability,” he said.

A fluid approach

“It’s quite a large market, and one that has been fragmented with lots of smaller, specialised businesses,” said Stephen Forbes, executive general manager, Motion Fluid Solutions.

“A key advantage of us having these specialised businesses under the one umbrella is it really makes it a lot easier for customers. We only provide products that meet strict Australian standards and can provide technically precise solutions that industries like food and beverage industries require.”

Importantly, Forbes stresses that the consolidation of brands under the Motion banner will not come at the expense of the small business mindset.

“It’s still vital that we have regional sales reps with strong local connections and knowledge,” he said.

“But as part of Motion, they also have access to our extensive network of expertise, which will help them deliver the right solutions and advice to their customers.”

Subheading: A solutions-focussed industrial supplier

Meanwhile, Kerwin is enthusiastic about the opportunities that are unfolding in the industrial solutions space.

“We’ve got a solid foundation in the bearing, power transmission and mechanical drive solutions space, largely due to the relationships forged over the years with our legacy companies BSC and CBC,” said Kerwin.

“What’s exciting is being able to customise solutions so that businesses don’t have to consult with various suppliers to get what they need.”

Crucially, Kerwin says, being a customer of any one of Motion’s divisions means customers can benefit from the resources and experience shared between them.

“Our purpose is to keep the world moving,” he said.

“That is what our customers want. They want to keep producing and maintaining their equipment to keep them moving, productive, and profitable.”

MOTION CONTROL www.foodmag.com.au | May 2024 | Food &Beverage Industry News 21

Motion provided a solution for one of Australia’s largest bottlers. (before)

Motion recommended the Gates Poly Chain GT Carbon for the client. (after)

F TO MOST AREAS Scan to visit supagas.com.au Liquid NitrogenCarbon Dioxide Dry Ice

The Gas Solution For Your Business

Supplying

Bec Hardy Wines: A legacy of innovation and sustainability

Richard Dolan, director of sales and marketing at Bec Hardy Wines, discusses the company’s success and growth, backed by multi-generational talent Bec Hardy, Adam McCleery writes.

Nestled in the heart of Australia’s wine country lies a legacy spanning six generations, embodied by Bec Hardy, a name synonymous with innovation and sustainability in winemaking.

Richard Dolan and his wife, Bec Hardy, a sixth-generation member of the renowned Hardy wine family, share the story of their legacy spanning back to the 1850s in South Australia when the Hardy family help establish the South Australian wine region.

Hardy’s parents ventured into their own wine business in 1980, and in 2011, Dolan and Hardy joined the family enterprise.

In July 2020, they took over the majority ownership, marking the latest

generational shift of the family

Hardy, as the first female vintner in her family, drew inspiration from strong matriarchal figures such as Dr. Barbara Hardy AO, an influential environmentalist, when stepping into the role that had been waiting for her.

“The family and the company have a truly unique history and heritage,” said Dolan.

“Hardy’s have been making vine in South Australia since the 1850s. Hardy’s great-great-great grandfather is regarded as the father of the South Australian wine industry, which is a unique history and heritage in the space.”

Dolan said he and Hardy were extremely proud to be the latest custodians of the family business.

The family’s commitment to sustainability is evident in their wine production, with efforts to minimise environmental impact at every stage.

Initiatives include biodiversity projects, partnerships with conservation organizations, and even embracing native wildlife on their vineyard premises.

This focus on environmentalism was another long-established part of the family business, thanks in no small part to the leaders who came before.

“Dr Hardy helped start a foundation that has helped converse large swaths of land in South Australia, a piece of land the size of Luxemburg,” said Dolan.

“That heritage, not only in wine, but in conservation and environmentalism is

why sustainability plays a significant role in our business.”

Dolan said a focus on sustainability and environmentalism was always an ongoing enterprise.

“For us, it’s a journey not a destination. There’s always more to do and more you can do,” he said.

“We might not be doing 100 per cent of what we are capable of with an unlimited budget and resources, but we are doing everything we can to lighten our footprint at every stage of the production process.

“Whether that’s the vineyards, bottling, labelling, our use of dry goods, packaging transport. All of that, everything, it comes down to a consideration for the natural

22 Food &Beverage Industry News | May 2024 | www.foodmag.com.au MEET THE MANUFACTURER

Images: Bec Hardy Wines

Bec Hardy Wines owners, Bec Hardy and Richard Dolan, combine family legacy, environmentalism, and innovation to create award winning wines.

environment and habitat.”

Bec Hardy Wines also works closely with local organisations and key stakeholders when it comes to identifying the right solutions around improved biodiversity and sustainability.

“We have been improving the biodiversity at our vineyards through local partnerships which has seen us plant 1200 new natives at one of our vineyards. Which also helps provide a corridor for wildlife,” said Dolan.

“We sponsor organisations such as the Nature Foundation and Koala Life, which aims to breed a disease-free population of koalas.”

Thinking outside the box, while consulting with local flora and fauna experts has proven to be an invaluable tool for the Hardy family’s environmentalist goals.

“Even just around Cellar Door, we have had to put a sign up because as part

of improving our biodiversity we have a population of native bush rats, which are native to the area and play an important role in the local habitat,” said Dolan.

“It’s amazing what happens when you give nature a helping hand.”

“After the prep pruner goes in July, we send 20 sheep into a vineyard.

This approach also lends itself to the generational scope with which Dolan and the rest of the family look at the business.

“We have been improving the biodiversity at our vineyards through local partnerships which has seen us plant 1200 new natives at one of our vineyards.”

Another example of how Bec Hardy Wines adapts to the local environment and aims to be as sustainable as possible, where possible, is through the use of sheep to help graze and clear away invasive weeds.

“The sheep are consuming weeds, a lot of which are introduced in the area. The sheep form a great function in the vineyard especially during winter,” said Dolan.

Dolan said the multi-generational aspect of Bec Hardy Wines is something they want to continue to build upon for the next generation, to continue the family legacy.

“Our vision is to build the company up even more and we have set a 25-year time frame for the transition the next generation of Hardy’s,” he said.

“Everything we do has a generational objective, to leave the business in a better

financial and sustainable position for that next generation to usher forward.

“This is great because, unlike a lot of corporates, we have short- and mediumterm profitability to consider but we are equally taking a generational view, whether that be in vineyard acquisition or management.”

This forward-thinking approach, with an eye on heritage, has also helped Bec Hardy Wines build a strong and unique local presence.

“Bec’s father is one of the country’s leading viticulturists, and he knows the soil in McLaren Vale as well as anybody, and its this sort of local knowledge which is passed down from generation to generation,” said Dolan.

“It’s often interesting when you listen to the stories from everyone who’s lived in the area for multiple generations, all of them have a connection to the land and passing on knowledge is very important.”

www.foodmag.com.au | May 2024 | Food &Beverage Industry News 23 MEET THE MANUFACTURER

Bec Hardy Wines has won a string of awards including Australian Wine Company of the Year and Australian Winemaker of the Year.

Bec Hardy Wines offers a wide range of premium wines for every occasion.

Bec Hardy is a sixth-generation member of the Hardy family and she continues the family legacy of expert winemaking.

MEET THE MANUFACTURER

Dolan said research had shown that some of the soils in the region were hundreds of millions of years old, combined with some vines which are at least 140 years old, which all combine to help develop some of the best wines coming out of the South Australian wine regions.

Capitalising on what the region has

to offer, and the family’s winemaking expertise, has resulted in a string of wine and business awards for Bec Hardy Wines.

Including Australian Wine Company of the Year in 2012 and 2014, along with Australian Winemaker of the Year 2012 and 2018.

Proving that the legacy of winemaking expertise being passed

down from generation to generation is continuing to provide some of the best wine and winemakers in the country.

On-top of this approach, Bec Hardy wines also puts emphasis on the strong matriarchal presence Hardy herself was lucky enough to grow up around.

“As part of our continued development, we have a real interest in

female winemakers,” said Dolan.

“There is a massive underrepresentation in the industry, they account for just one in ten winemakers in Australia.

“When we acquired the business, we set the vision to freshen up the winemaking style and take it in a slightly different direction.

“Part of our desire was to also provide a strong female role model for our daughter, we set about that task and hired a new female winemaker to join our team.”

Dolan said that choice to hire Bec Swincer as a new winemaker has already paid off for the business and will continue to do so into the future.

“Her introduction to the business has been amazing and our wines have seen another step-up thanks to her expertise,” he said.

“She is in to her third and fourth vintages of red wines, fifth vintages of whites and some really impressive wines coming through which we are excited about.”

For Dolan and Hardy, wine making is more than just a business; it’s a way of life—a way of preserving tradition while embracing change and sustainability for generations to come.

And as the family looks to the future, Bec Hardy Wines stands as a beacon of inspiration for the Australian wine industry, by embodying the spirit of innovation, sustainability, and family tradition. F

Sustainability and environmentalism are always at the forefront of the Hardy family’s mind, in all areas of production and manufacturing.

Richard Dolan said that he and Hardy are excited to introduce the next generation of the family to the family business.

AGRICULTURE FARMING EDUCATION WASTE

MANAGEMENT RESOURCE MANAGEMENT

CONSERVATION MANUFACTURING RESOURCES

ENERGY HEALTH & SAFETY INFRASTRUCTURE

ENGINEERING MINING CONSTRUCTION

QUARRYING AGRICULTURE FARMING EDUCATION

WASTE MANAGEMENT RESOURCE MANAGEMENT

CONSERVATION MANUFACTURING RESOURCES

ENERGY HEALTH & SAFETY INFRASTRUCTURE

ENGINEERING MINING CONSTRUCTION

QUARRYING AGRICULTURE FARMING EDUCATION

WASTE MANAGEMENT RESOURCE MANAGEMENT

CONSERVATION MANUFACTURING RESOURCES

ENERGY HEALTH & SAFETY INFRASTRUCTURE

ENGINEERING MINING CONSTRUCTION

QUARRYING AGRICULTURE FARMING EDUCATION

WASTE MANAGEMENT RESOURCE MANAGEMENT

SEARCH FOR TOP INDUSTRY TALENT THROUGH OUR JOBS BOARD.

CONNECT WITH ALIGNED CANDIDATES.

BOOST YOUR CHANCES OF FINDING SKILLED APPLICANTS.

SCAN TO CREATE AN ACCOUNT TODAY AND DISCOVER YOUR PERFECT MATCH!

POWERED BY CAREERONE

Digitalisation of flow measurement and its benefits

The importance of digital connectivity and hygiene in the industrial sector, particularly in ensuring product quality and meeting regulatory standards, can’t be overstated. Food & Beverage Industry News reports.

The benefits of real-time data accuracy and quality assurance in digitalised processes is a critical part of manufacturing, with simplicity and effectiveness of a plugand-play installation being one of the more obvious benefits.

With the potential for seamless integration with existing systems, ifm’s Hygienic Flow Meter with IO-Link presents a cutting-edge solution for the continued evolution of monitoring technology.

ifm specialise in manufacturing sensors and control systems, with a wide range of products on offer for food and beverage manufacturing.

IO-Link is a standardised, serial communication protocol used in industrial automation, serving as an interface between sensors or actuators and the higher-level control system.

Overall, IO-Link offers benefits such as increased flexibility, easier configuration, enhanced diagnostics, and seamless integration, making it a popular choice for industrial automation applications.

For example, the ifm Hygienic Flow Meter with IO-Link is helping to revolutionise the way food products

accuracy and real-time data transmission capabilities.

Glenn Thornton, ifm’s national product and brand manager, spoke about the need for such technology and the role it plays in helping to future-proof businesses.

“Real-time data is a very important point for us at ifm, and this solution provides transferable, readable, and actionable insights,” said Thornton.

“That traceability creates a new level of improved quality assurances. Every aspect of your operation is within reach, empowering you to make informed decisions and optimise your processes like never before.”

Gone are the days of relying on multiple measuring points, which in turn creates the opportunity to redistribute crucial labour elsewhere.

With IO-Link technology, the Hygienic Flow Meter ensures seamless digital data transmission, providing complete transparency from start to finish.

The Hygienic Flow Meter offers a wide variety of applications, from detecting flow rate and total volume, to monitoring flow direction and medium presence. This device delivers a comprehensive overview of your production line.

Also, with conductivity and temperature data transmission, you’ll have everything you need to maintain quality and consistency.

“We understand the importance of simplicity in the workflow,” said Thornton.

“That’s why we’ve designed the Hygienic Flow Meter for effortless integration.”

With standard installation dimensions, a range of seals and adapters, and a user-friendly app-based interface, making for an efficient set-up.

“Plus, our patented cables and M12 connection ensure a fast, waterproof, and error-free connection to your data infrastructure,” said Thornton.

“Quality is non-negotiable in the

food industry. That’s why the Hygienic Flow Meter undergoes rigorous testing to ensure long-lasting performance.”

From temperature shock tests to pressure peak simulations, this device is built to withstand the most demanding conditions.

“So, you can trust that your measurements are accurate, every time,” added Thornton.

“As a magnetic-inductive flow meter, the Hygienic Flow Meter is at the forefront of innovation in the food industry, by providing precise measurements and real-time data transmission, it’s helping set a new standard for efficiency and reliability.”

The solution also plays a significant role in the context of digitalisation and Industrial Internet of Things (IIoT) initiatives.

One of the main advantages of IO-Link is its ability to provide extensive configuration options and diagnostic information for connected devices, such as when paired with ifm’s Hygienic Flow Meters.

This compatibility allows for remote parameterisation, monitoring, and troubleshooting of sensors and actuators, enhancing overall system efficiency and reliability.

“What you have is immediate notifications of any deviations, any worrisome fluctuations, any erroneous fluctuations, and alike,” said Thornton.

“Along with dosing, colouring, mixing, and batching.

“The digital signal is a lot purer than what is previously been done.”

Thornton also said part of the revolution being provided by the Hygienic Flow Meters come from the materials used in the solution and the ease with which it can be put into practice.

“It’s as simple as one single plug in the back. You plug it in, and you are now into the digital world,” he said.

The digitalisation of the flow meter also helps to reduce the risks associated with human error, while also allowing

for timely responses to any issues which may arise.

On top of this, the Hygienic Flow Meter with IO-Link also has a protection rating of IP67 (waterproof) and IP69K (protection against ingress of dust, high temperature, and highpressure water.)

Both these ratings show the solution is able to withstand robust washdown routines, which are very common and supremely important to the manufacture of foods and beverages.

The Hygienic Flow Meter is also perfectly suited to be paired with other ifm product solutions such as conductivity sensors, pressure sensors, and temperature sensors

The flow meter’s ability to provide detailed device information and support for data exchange also enables intelligent and connected manufacturing processes, leading to improved productivity, flexibility, and predictive maintenance.

With its advanced features, seamless integration, and unwavering reliability, it’s poised to transform the way you measure and monitor your production processes. F

INSTRUMENTATION 26 Food &Beverage Industry News | May 2024 | www.foodmag.com.au

Images: ifm

The Hygienic Flow Meter with IO-Link offers real-time data and quality assurance.

The Hygienic Flow Meter was designed with effortless integration in mind.

mice2024 serving coffee

REGISTER YOUR TICKET FOR THE INDUSTRY EVENT FOR CAFÉS AND FOOD SERVICE

12—14 MAY 2024

MELBOURNE CONVENTION AND EXHIBITION CENTRE

INTERNATIONALCOFFEEEXPO.COM tickets on s ale now #TICKETS PLATINUM SPONSORS

Sustainable packaging innovation ahead of product launches

As COPAR edges closer to starting production in Australia, the alternative packaging business is continuing to make positive progress across multiple markets. Food & Beverage Industry News reports.

COPAR continues to innovate in exciting ways ahead of an Australian rollout of its wheat straw alternative packaging options.

Recent trade shows have highlighted the urgency being felt by the food and beverage industry when it comes to finding viable packaging options that can meet fast approaching sustainability and efficiency targets. Both locally and globally.

“I noticed at one of the trade shows we did last year, the difference in conversation from then to now shows people are doing their homework,” said Angela Jones, sales manager, COPAR.